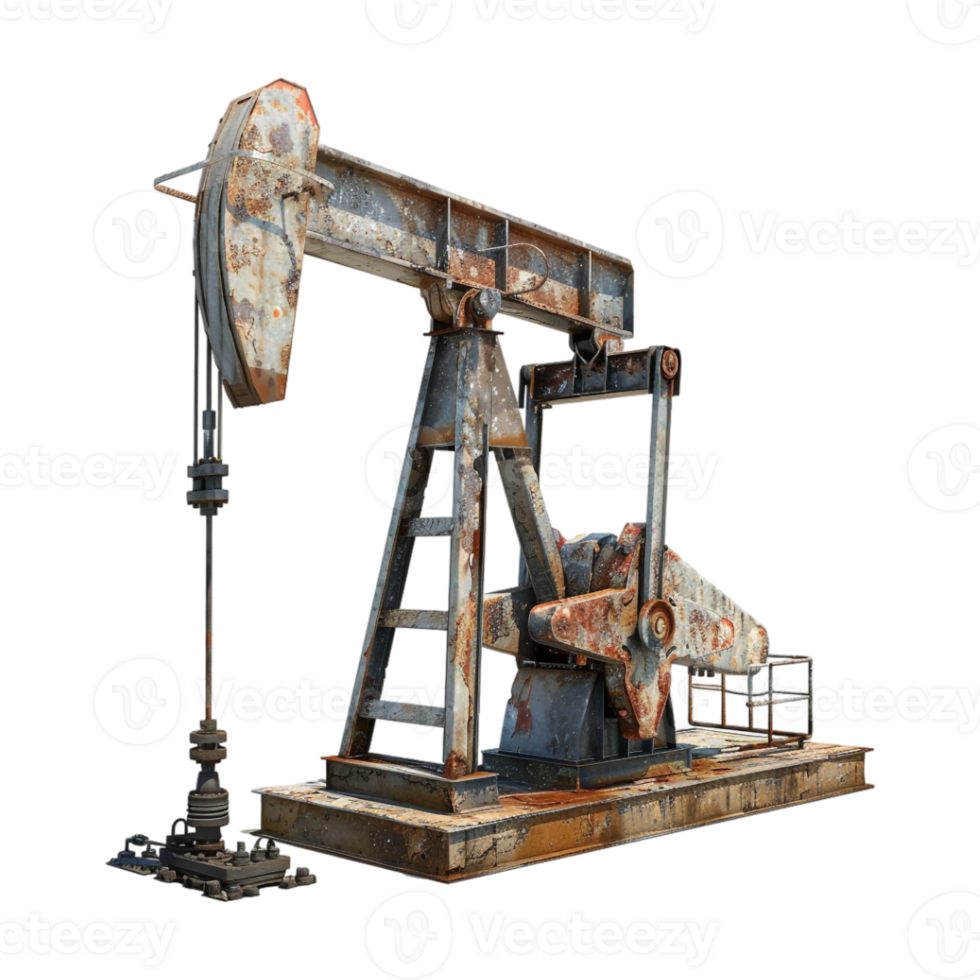

Oil and gas drilling is a complex process that requires specialized equipment to explore and extract petroleum and natural gas from beneath the Earth’s surface. Each piece of drilling equipment plays a crucial role in ensuring the operation’s success, safety, and efficiency. Among the most important equipment used in oil and gas drilling are the drilling rig, drill bit, mud pumps, blowout preventer BOP, and drilling fluids systems. The drilling rig is the backbone of any drilling operation. It provides the structure and machinery necessary for the actual drilling process. The rig is designed to support the heavy equipment used to drill the well and is capable of withstanding extreme pressure and harsh environmental conditions. It includes various components like the derrick, which is a tall structure that supports the drill string and other equipment, and the power system, which provides the necessary energy to drive the drilling operations. Rigs can be either land-based or offshore, with offshore rigs specially designed to handle the challenges of working at sea.

The drill bit is another critical piece of equipment. It is the cutting tool used to break through rock formations and create a borehole. Drill bits come in various designs, with the most common types being roller cone bits and fixed cutter bits. The selection of the drill bit depends on the type of rock and the depth of the well being drilled with oil drill machine. The bit must withstand extreme heat, pressure, and abrasive forces as it penetrates deeper into the Earth. Mud pumps are used to circulate drilling fluids, often referred to as mud, through the wellbore. Drilling mud serves several purposes: it cools and lubricates the drill bit, helps to lift rock cuttings to the surface, and controls pressure in the well. Mud pumps are designed to pump high-pressure fluid into the wellbore to keep it circulating. This process helps maintain the integrity of the well and prevents potential issues like wellbore collapse or blowouts. The blowout preventer BOP is a crucial safety device used to control high-pressure hydrocarbons during the drilling process. Located at the top of the well, the BOP is designed to seal the well in the event of a blowout, preventing the uncontrolled release of oil or gas.

Blowouts can cause catastrophic damage, so the BOP is a vital safety feature in preventing these dangerous incidents. Finally, the oil and gas equipment fluids system is responsible for maintaining the proper composition and circulation of drilling mud. The system includes tanks, mixers, and other equipment that ensure the mud is mixed and treated properly, enabling it to flow consistently throughout the drilling process. This system ensures that the mud is capable of performing its multiple functions, including the transport of debris, lubrication, and pressure control. In conclusion, oil and gas drilling equipment is essential for the safe and efficient extraction of hydrocarbons from the Earth. Each piece of equipment, from the rig to the blowout preventer, works in tandem to facilitate the drilling process and ensure operational success. As technology continues to evolve, these tools become more sophisticated, enhancing safety, productivity, and environmental responsibility in the oil and gas industry.